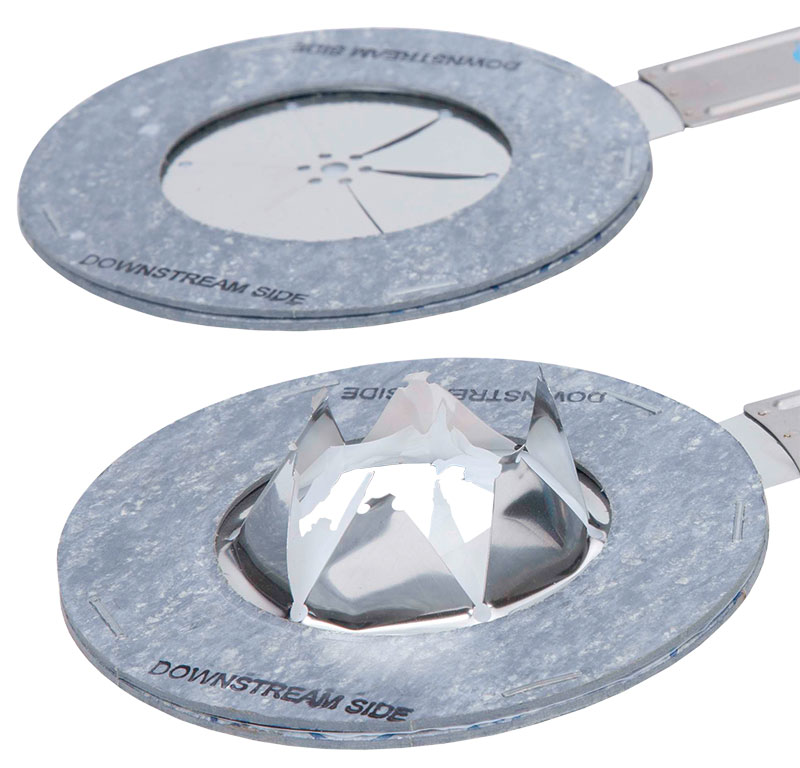

Isolation Seal (IS) Rupture Disc

The Isolation Seal (IS) rupture disc is a flat composite rupture disc that installs between standard bore 150# ASME bolted flanges. The recommended operating pressure is 50% of the rupture disc’s minimum burst pressure.

IS discs are typically used for:

- Low pressure relief of atmospheric storage tanks.

- Downstream relief valve manifold isolation.

- A corrosion barrier.

- An environmental seal.

The IS is available in two designs:

- IS-1 – Bursts in one direction only.

- IS-2 – Bursts in an identical rating in either positive or vacuum direction.

The IS disc includes a high-visibility flow direction tag for easy installation, correct orientation, and at-a-glance inspection. All IS rupture discs 1″ (25 mm) nominal size and above include a flow direction tag.

Seating configuration: Flat seat, no holder required

Burst pressure range: See table 7, Minimum/Maximum Burst Pressures for IS

Rupture Discs.

Table 2A – Burst Tolerance and Maximum Recommended Operating

Pressures.

Available materials:

Top section – 316SS, alloy 600, alloy 400, nickel

Seal – Fluoropolymer or polyethylene

Includes a non-asbestos gasket on each side of the disc for easy handling

and installation.

Manufacturing range: See table 2, Manufacturing Ranges

Special and reduced manufacturing ranges are available upon request.

Available in a variety of materials to resist highly corrosive media and atmospheric conditions.

Specified and MIN/MAX Rating Types are also available.

GIVE US A SHOT.

We’ve spent decades refining our manufacturing processes with efficiency and agility in mind. We’re ready to put our methods to work for you.